Каждый день мы работаем для осуществления ваших идей и проектов в сфере освещения

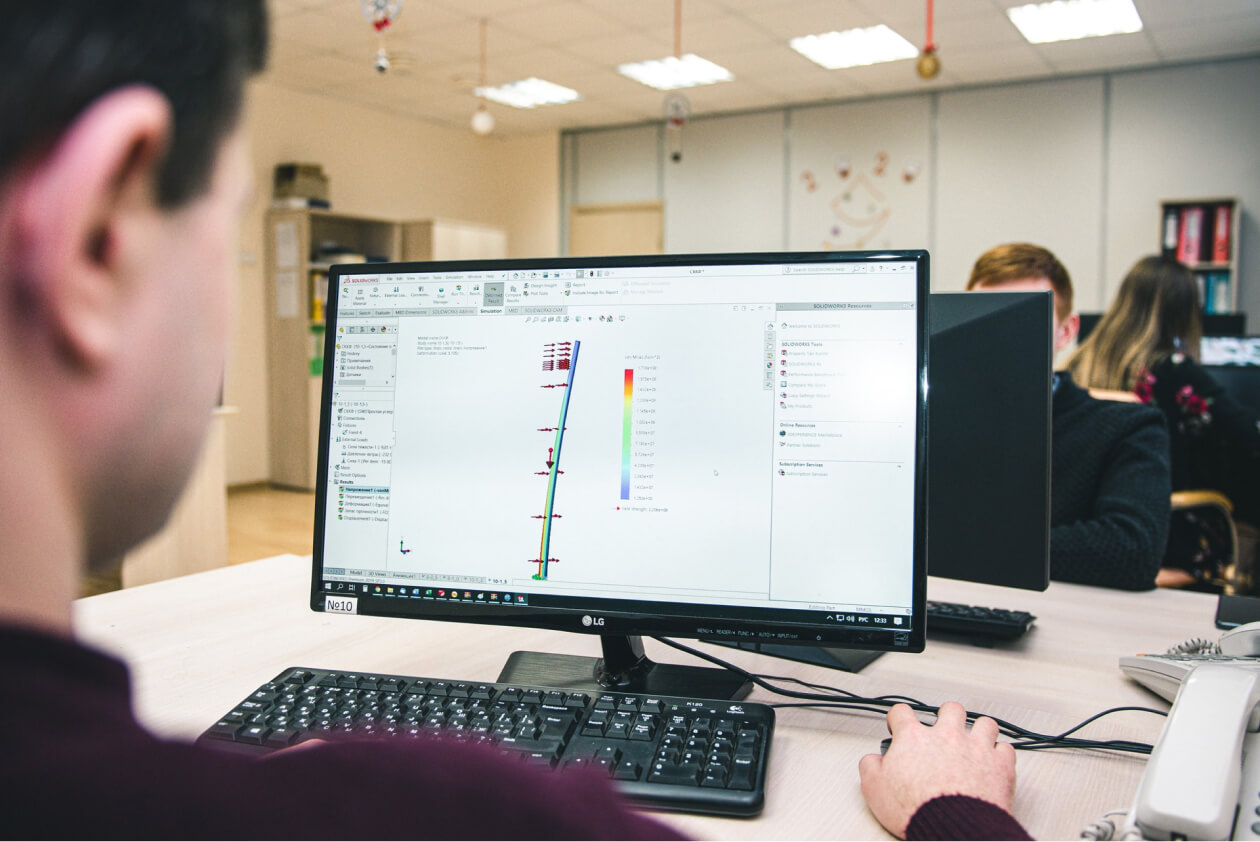

Проектирование и градостроительство 21 века — это персональный подход, отражающий мировоззрение и индивидуальность конкретного заказчика. В нашей компании работают специалисты с художественным образованием, которые позволяют Вам полностью реализовать свои идеи в дизайне опор и кронштейнов. Короткий срок разработки проектов опор и кронштейнов по требованиям заказчиков, а также обоснование надежности их эксплуатации при плановых нагрузках обеспечиваются применением многофункционального программного комплекса LIRA SOFT

Качественную продукцию можно изготовить только из качественных материалов и комплектующих. Мы используем для производства осветительных приборов европейские комплектующие, которые подтвердили высокие характеристики в эксплуатационных условиях

Все технологические процессы по изготовлению опор кронштейнов и осветительных приборов осуществляется в строгом соответствии с разработанными техническими условиями. Для производства опор применяется установленная на производстве в 2015 г. современная линия по производству конусных круглых и граненых опор, включающая полный цикл производства: от размотки рулонного железа до гибки листогибом-тандемом длинной 14 м и автоматической сварки. Готовые изделия полностью соответствуют стандартам Таможенного Союза и Европейского Союза

Опоры, кронштейны, металлические части осветительных приборов и металлоконструкции, обрабатываются для защиты от влажности и агрессивных сред. Наша компания предлагает три типа покрытий: